'Stains' on frozen prata: Contamination during manufacturing unlikely, says manufacturer

The "stains" found on frozen prata from a Spring Home family pack were unlikely to have occurred during manufacturing, the manufacturer told Stomp.

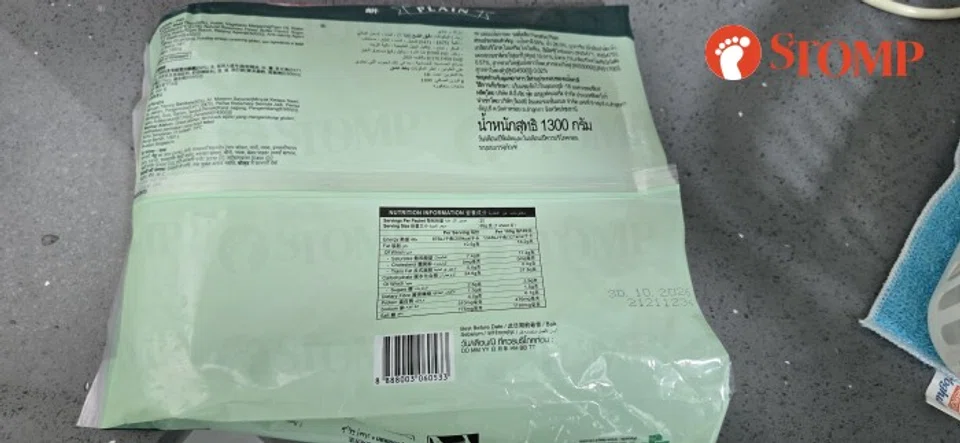

Stomp reported on April 22 that Stomper Mandy had discovered greenish black spots on several pieces of frozen prata she bought from the FairPrice Xtra outlet at AMK Hub.

In response to a Stomp query, FairPrice Group said: "We have conducted a thorough investigation on this isolated incident and the supplier has since tightened its quality checks to prevent recurrence."

A spokesman for Tee Yih Jia Food Manufacturing told Stomp that the company collected the prata from the retailer to investigate.

"Based on the information provided by the customer, we are able to track details such as the product's manufacturing date, external microbe analysis test, routine sensory test, delivery information, cold room temperature records, truck temperature and related surveillance data," said the spokesman.

"Our investigation showed that there was no non-conformance detected for the product and accordingly, the possibility of contamination or temperature abuse during manufacturing is unlikely.

"Temperature abuse during transportation can also be ruled out as its impact would affect the entire lot rather than a single packet.

"There were 2,127 cartons produced on the same line on the same date on Nov 21, 2024, there is no similar feedback for the above batch till date."

These findings were shared with the Stomper and FairPrice Group, added the spokesman.

"Our next steps will be to log this case into our records and continuing to monitor for similar product quality feedback especially from the batch code identified.

"Tee Yih Jia will also reinforce cold chain handling protocols with our logistics partners and retail distributors, particularly during unloading and shelf display to avoid cold chain breakdown.

"Internally, we will undertake preventive briefing on this incident with our quality assurance and production teams with emphasis on strict adherence to cold chain practices post-IQF (individual quick freezing) to final delivery and refresher training for quality assurance, packing and warehouse teams on cold chain handling and visual inspection protocols."

The spokesman explained: "Mould is unable to propagate at freezing temperatures of -18°C or below.

"The presence of mould on a frozen product suggests contamination prior to freezing or temperature abuse during storage or distribution, such as intermittent thawing or condensation that promotes microbial growth before the product is refrozen."

Other contributing factors include:

- Temperature abuse occurring at the selling point, where the product is left out of the freezer for a period of time by other customers who place it in their shopping trolleys and baskets, and not returning the products to the freezer upon deciding not to purchase after all.

- Overfill of merchandise in freezers blocking air ventilation and preventing cold air from reaching the product.

- Products being stored at a dead spot during logistics and storage resulting in unfavourable storage temperature as well as other possible mishandling issue.

See something interesting? Contribute your story to us.

Explore more on these topics